Introduction:

MLP Logistics is a company based in County Carlow. The company runs a warehouse and storage facility. The items of stock and the origins vary across the globe.

The management staff of MLP Logistics have assessed the workplace of one of its warehouses as unsafe as there has been a number of reportable accidents within the previous twelve months and it is understood that some of the daily activities are potentially hazardous and at risk of further injury to employees if not remedied.

A review on current workplace activities has been carried out in the following report with the aim to promote, prevent and continually assess Health and Safety in the workplace. It has been reported that over the past twelve months there has been an increase in manual handling type accidents. The main concern is that employees are suffering from lower back pain as a result of improper use of equipment, incorrect techniques in lifting and lowering of stock and insufficient mechanical devices to assist in the lifting of the stock. After meeting with management and staff it was agreed that a detailed examination of manual handling activities will be carried out within the organisation. The area of concern is in the warehousing department and the safe handling of equipment and the restocking of shelves. Provided will be a full list of current manual handling practices together with any recommendations for improvement, costing and a final conclusion.

Aim:

This report aims to improve the safety of all employees and employers in the workplace and develop a system of control techniques put in place to monitor the effectiveness of these control measures while ensuring to consistently update any relevant legislation.

Objective:

The objective is that throughout thorough investigation into the current health and safety and manual handling practices in MLP Logistics, clear assessment and recommendation will applied in order to promote a safer workplace.

Safety, Health and Welfare at Work Act 2005 (SHWW)

Before the legislation itself, it is vital that the management and staff fully understand the reasons behind the need for a change in the workplace.

The Safety, Health and Welfare at Work Act puts into place specific duties on both the employees and the employers and the legislation they must adhere to and the four key features of the SHWW act 2005 are;

- The requirements for the control of the safety and health at work

- The management, organisation and the systems of work to achieve those goals

- The responsibilities and roles of employers, employees, self-employed and others

- The enforcement procedures needed to ensure that the goals are met

- The General Application Regulations 2007 (GAR) Manual Handling of Loads lays out a clear set of regulations to be followed

- Schedule 3 of the SHWW act is the Hierarchy of Control as seen below in figure 1 and reduces the risk of injury by eliminating and or reducing that particular risk, this is a key factor in establishing the problem and offers a process of elimination to solving the risk in the workplace.

Figure 1:

Ergonomics:

As stated by the Health and Safety Authority, ergonomics is fitting the task to the person, the benefits for the company, employees and the employer include,

- Safer practices

- Less work related injuries

- Less stressful working environment

- Reduced absenteeism

- Reduced costs

- Healthier and happier workforce

- Higher productivity

Taking all of these benefits into account, it is clear that the warehousing department has had some difficulties. Consideration must be given to the size of the boxes being stacked on the shelves, for a single person the boxes are too wide and the contents are unstable and likely to shift making it a dangerous lift on a single individual, the lighting in between the rows of shelves in inadequate to perform the task.

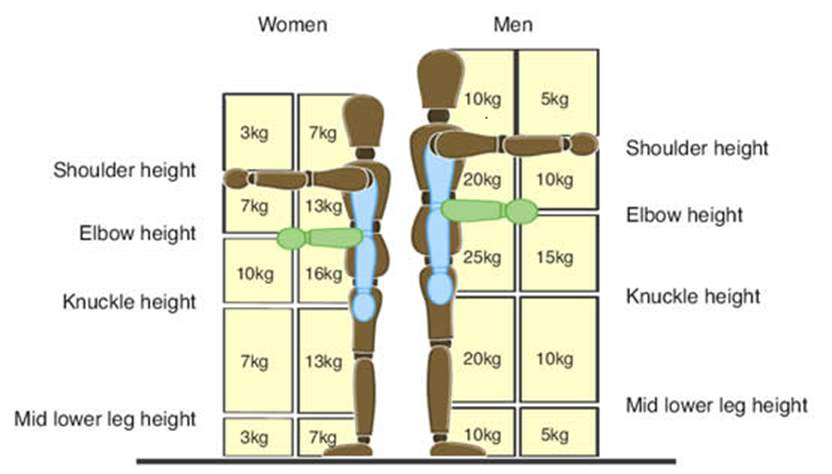

Figure 2: Shows the maximum recommended weights that a person should lift and lower and the differential weight shift as the object is moved away from the body, this diagram is in line with the legislation of manual handling tasks to the Health and Safety Act guidelines on lifting and lowering items.

Ergonomic Principles must be allowed to be freely carried out by the employee, these include;

- Maintaining a neutral posture

- Working in the ‘power’ or comfort zone

- Allow for movement and stretching

- Reduce excessive force

- Reduce excessive motions

- Minimise contact stress

- Reduce excessive vibration

- Provide adequate lighting

The employees have a part to play in this role, there must be common sense applied in carrying out these tasks in the warehouse, the employees must report any unusual activities or hazards they come across to the employer/manager. Also the management team must assess the workplace and ensure that the workplace is safe and not putting employee’s wellbeing at risk.

I have compiled a Risk Assessment (RA) set out to resolve any current issues.

TITLE: | R.A. WAREHOUSE 1a | RISK ASSESSMENT NUMBER: | 5 | ||||||||||

ACTIVITY AREA: | AISLE 1-16 | DATE PREPARED: | 10/06/19 | ||||||||||

HAZARDS | LIKELIHOOD | SEVERITY | RISK SCORE | ||||||||||

REF. | KEY HAZARDS ASSOCIATED WITH THE A/M ACTIVITY. | 1 VERYUNLIKELY

2 UNLIKELY

3 LIKELY | 4 VERY LIKELY | 5 CERTAIN | 1 MINOR IMJURY NO TIME OFF | 2 INJURY UP TO THREE DAYS OFF | 3 REPORTABLE CONDITION | 4 MAJOR INJURY LONG TERM SICK | 5 DEATH | LIKELIHOOD X SEVERITY | |||

1 | MOVING BOXES FROM DELIVERY TRUCK |

| * | 2 | |||||||||

2 | STACKING BOXES IN THE AISLE 1-16 | * | * | 6 | |||||||||

3 | STACKING VEHICLE | * | * | 12 | |||||||||

RA SCORES: | 10 + VERY HIGH | 5-9 HIGH | 1-4 LOW | ||||||||||

NUMBER | DESCRIPTION OF HAZARD | CONSEQUENCE OF HAZARD | PERSONS AT RISK | CURRENT CONTROL MEASURES | RISK (LxS) = VH/H/L |

1. | MOVEMENT OF BOXES MANUALLY FROM DELIVERY TRUCK TO WAREHOUSE | SPRAINS, BACK PAIN, MINOR INJURY | 1. EMPLOYEE STAFF | STAFF TRAINED IN M.H. ALL STAFF REPORT ANY DEFECTS TO MANAGEMENT | LOW |

2. | STACKING BOXES IN THE AISLE 1-16 | FALLS, BROKEN BONES, RISK OF INJURY | 1. EMPLOYEE STAFF | STACKING MACHINE OPERATOR, ALL STAFF IN HIGH VIS VESTS, PPE TO BE WORN | HIGH |

3. | STACKING VEHICLE MOVEMENT IN AISLES, RISK OF COLLISION WITH STAFF | BROKEN BONES, DEATH | 1. EMPLOYEE STAFF 2. VISITORS | VEHICLE TO BE GUIDED BY STEWARD IN HIGH VIS VEST, DO NOT EXCEED 5KPH, HAZARDS LIGHTS ON | VERY HIGH |

Risk Factors:

These include the situations before any lifting or lowering of equipment that the individual carrying out the task must understand and the potential risks of injury to them. They are assessed as follows;

- T – TASK = The requirements of the activity

- I – INDIVDUAL = The physical effort required

- L – LOAD = Characteristics of the load

- E – ENVIRONMENT = The characteristics of the working environment

Recommendations:

- Manual handling must be certified at least every two years by a QQI Level 6 Certified Manual Handling Instructor and be specific to the work being carried out.

- Employees must know and understand the correct techniques for lifting and lowering items in the warehouse.

- There must be adequate room for movement of the boxes in question.

- From an investigation into the recent workplace accident it is clear that 80% of the boxes of parts delivered to the warehouse is not suitable for a single person to lift.

- For stacking onto the higher part of the shelves there will need to be a stacking machine purchased and an operator selected to undergo training.

- The lighting is not suitable for the work, each aisle must be correctly lit up.

- There is not the correct amount of safety signage displayed throughout the warehouse aisles.

- Employees have not been issued with the appropriate Personal Protective Equipment (PPE) since 2016, this must be reviewed and monitored accordingly, as stated previously there is a responsibility to both the staff and the management to monitor and report this.

In order to reduce musculo-skeletal injury it is recommended that a QQI Level 6 Manual Handling Instructor deliver a training day and will give the staff the required knowledge and information to reduce the potential risk of workplace injury. The employees will do on-site training and practice the correct manual handling techniques specific to their working environment.

A timeline of 8 weeks has been set in place from the 1st day of July and this will give sufficient time to train the staff and implement any recommendations including the purchasing of equipment.

Costing:

- Manual Handling for 6 employees = €300

- Purchase PPE = €650

- Stacking machine = €1250

- Safety Signage = €180

- Lighting = €120

TOTAL = €2500

Conclusion:

As the Health and Safety Officer in MLP Logistics I have compiled a Risk Assessment on the area of that is of concern in the workplace where there has been a number of accident/incidents in ‘Warehouse 1a Aisle 1-16’ and assessed the factors into three categories and at a training cost of €2500 to the business. This training is essential in the health and safety of the employees and covers all the legislation surrounding this field. I recommend that on an on-going weekly and monthly basis that checks will be carried out by me and the warehouse supervisor to ensure the standards laid out are being adhered to. There will be mandatory on the spot checks also to ensure that should any problem occur it will be dealt with immediately.

MLP Logistics

Health and Safety Officer

References: